As PiWars 2022 came to an end we'd decided we wouldn't carry on to the in person competition. There were lots of reasons; 2022 had been a tough year for free time with a bad job move and lots of events again. At EMFCamp we'd seen the Hacky Racers and enjoyed running our PiWars robot around the track and wondered about building our own Hacky Racer, so when the announcement about a robotic racing series came out I jumped at it.

I wanted to build something bigger than a PiWars robot but the scale and safety requirements of building a racer to ride in were too intimidating so the A2 class was where I focussed.

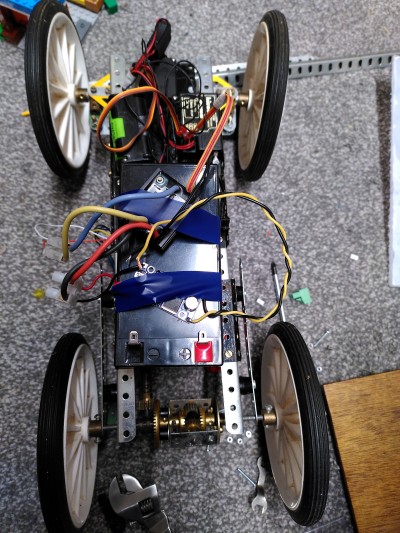

I really wanted to just get started so I had a dig around and found all my boxes of Meccano and parts modified to work with Meccano. When I was (much) younger I spent a lot of time building robots out of Meccano but I added a lot of motors, wheels etc. that had been adapted to fit on Meccano axles. I found a set of 170mm wheels that were a bit skinny and enough gears to make a diff. A quick 3D print made a miunting plate for a steering servo and with a motor off our 2021 PiWars entry I had a moving prototype.

Speed was a serious issue for this first prototype. The motors for our PiWars bot were meant to be faster than we needed but only by a factor of 2 and the arena for PiWars was only 1.5m across. Getting a faster motor was the next quest. I had a few options to consider:

- Buy a faster geared DC motor from a hobby robotics supplier

- Get an industrial type BLDC and find/make a drive

- Modify a BLDC drive from an e-bike/scooter

- Use a motor and controller intended for radio controlled cars

I spent a while window shopping around the problem. Faster geared motors weren't going to have the torque I wanted, the ones we had were already done of the most powerful I could find at a reasonable price. I have some experience with powerful BLDC drives from work but doing that in my free time as well didn't seem like a good idea, and the motors are really quite expensive. I looked at e-bike and scooter drives but they're too big or too difficult to integrate on a project this size. I'd probably go for one of those if I was entering the full size category. That left me with RC motor and drivers. This is a cost effective solution because there's a big market for these parts. They're also pretty easy to control from microcontrollers. There was still a question of whether to go for brushed or brushless motor and what sort of controller and battery to use.

I've had limited success with buying RC parts from eBay or other online stores in the past. Out of a single order of 4 "metal gear" servos there were at least 3 distinct different models shipped and only one of the four actually had metal gears. Similarly buying from Aliexpress can be hit and miss, I've had some good motors but I've also had a bag full of broken parts. For this project I decided to take advantage of expert advice and found a local RC model shop. We live near Falmouth and found Matt's RC Garage online. The owner is extremely knowledgeable and helpful once I'd explained to him we were looking to build a custom platform for an autonomous vehicle competition and offered some really helpful advice that definitely wasn't just trying to sell us the most expensive parts he had in the shop.

In the end I came away with a powerful brushed DC motor and good quality speed controller. A really nice LiPo pack with a hard case and a 50C discharge rate and a safety charging bag and balancing charger.

After some more fiddling with Meccano adapters I managed to get the motor mounted on the car with a Meccano gear box and took it for a spin. That was more literal than I'd expected. The thin wheels had limited grip and the acceleration was very fierce. The new car was doing doughnuts round our kitchen floor! It was also shaking itself to pieces as the Meccano gears and rods weren't balanced enough for the speed and power this new motor produces.